Introduction to Lean Systems

Lean System is a management philosophy focused on creating the most value for customers while minimizing waste—a principle that originated from the renowned Toyota Production System123. Imagine organizing your kitchen: you remove unused gadgets, keep essential tools handy, and arrange items to cook faster without any unnecessary steps. That’s Lean in action—eliminate what’s not needed and focus energy where it counts.

The core idea is simple: identify and remove anything that doesn’t directly contribute value to the customer. By doing so, businesses become more efficient, flexible, and responsive—embracing continuous improvement as a way of working145.

Types of Lean Systems

Modern Lean combines time-tested practices with practical tools. Here are the most widely recognized types:

Just-in-Time (JIT)

- Key Idea: Produce and deliver products exactly when needed, in the amount needed—no more, no less.

- Application: Used in production lines and supply chains to cut excess inventory and improve flow.

- Tool Example: Kanban cards/signals.

Kanban System

- Key Idea: A visual workflow management tool that signals what, when, and how much to produce or move6.

- Application: Widely used to manage inventory, manufacturing, software development, and project tasks.

- Tool Example: Kanban boards.

Kaizen (Continuous Improvement)

- Key Idea: Small improvements every day—by everyone.

- Application: From factory floors to customer service desks, encouraging teams to suggest and implement changes.

- Tool Example: Kaizen events, suggestion systems.

5S System

- Key Idea: Sort, Set in Order, Shine, Standardize, and Sustain for a clean, organized, efficient workplace7.

- Application: Any environment—offices, plants, hospitals—to reduce waste and increase safety.

Value Stream Mapping

- Key Idea: Diagramming every step in a process to spot and eliminate steps that don’t add value.

- Application: Used to identify bottlenecks or waste in manufacturing, logistics, or administrative workflow.

Lean Six Sigma

- Key Idea: Integrates Lean’s waste reduction with Six Sigma’s defect and variability control.

- Application: Used for process improvement and problem-solving, often in quality management.

- Comparison: Lean focuses on “speed and flow” (waste), while Six Sigma tackles “consistency and quality” (variability); together, they maximize efficiency and reliability6.

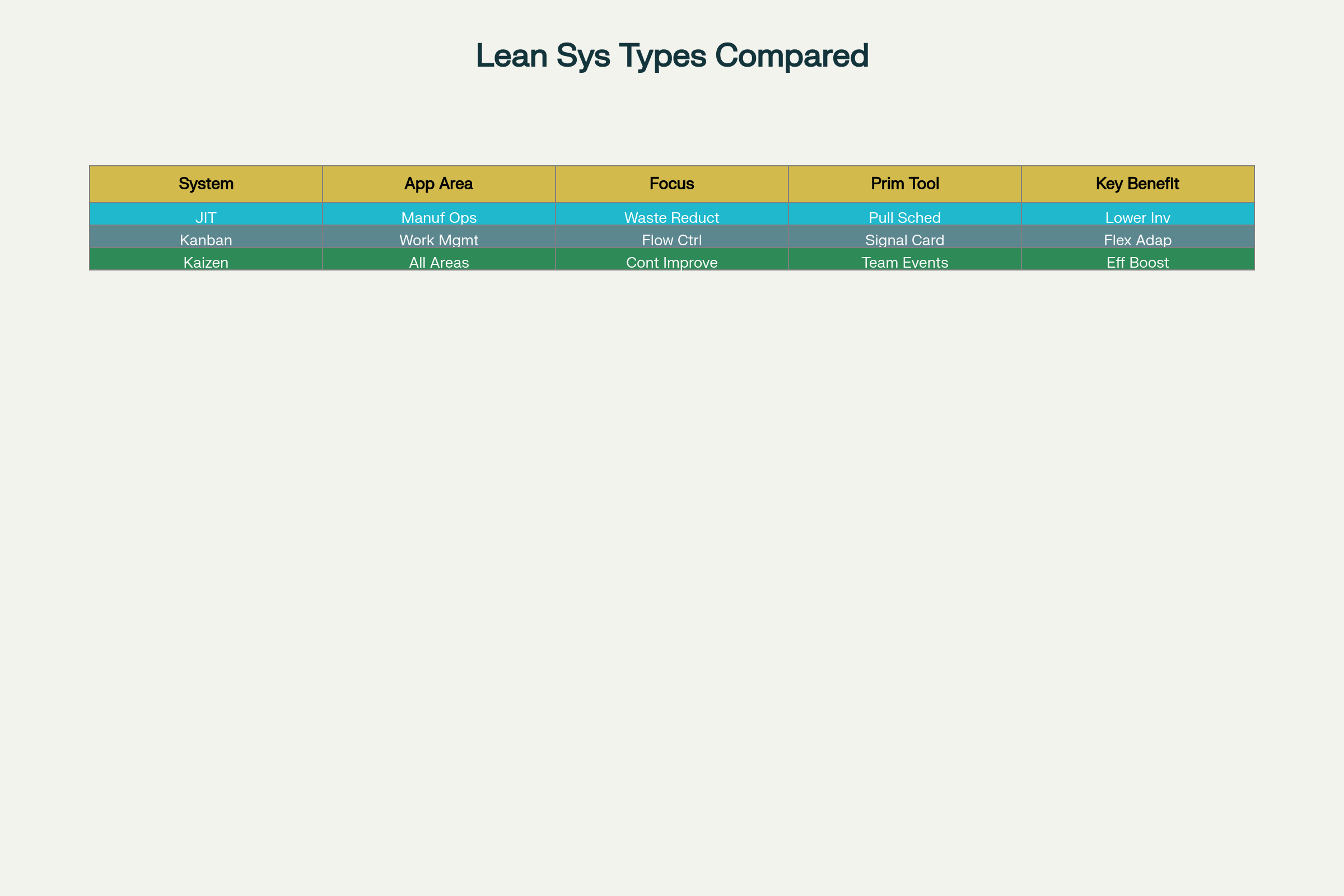

Comparison of Major Types of Lean Systems

Comparative Table: Major Types of Lean Systems

| Type | Major Application | Focus | Key Tools | Key Benefits |

|---|---|---|---|---|

| JIT | Manufacturing, Pharma | Inventory Reduction | Kanban, JIT | Low inventory, cost |

| Kanban | Production, Services | Workflow Management | Kanban board | Visual control, flow |

| Kaizen | All departments | Continuous Improvement | Suggestion box | Team empowerment |

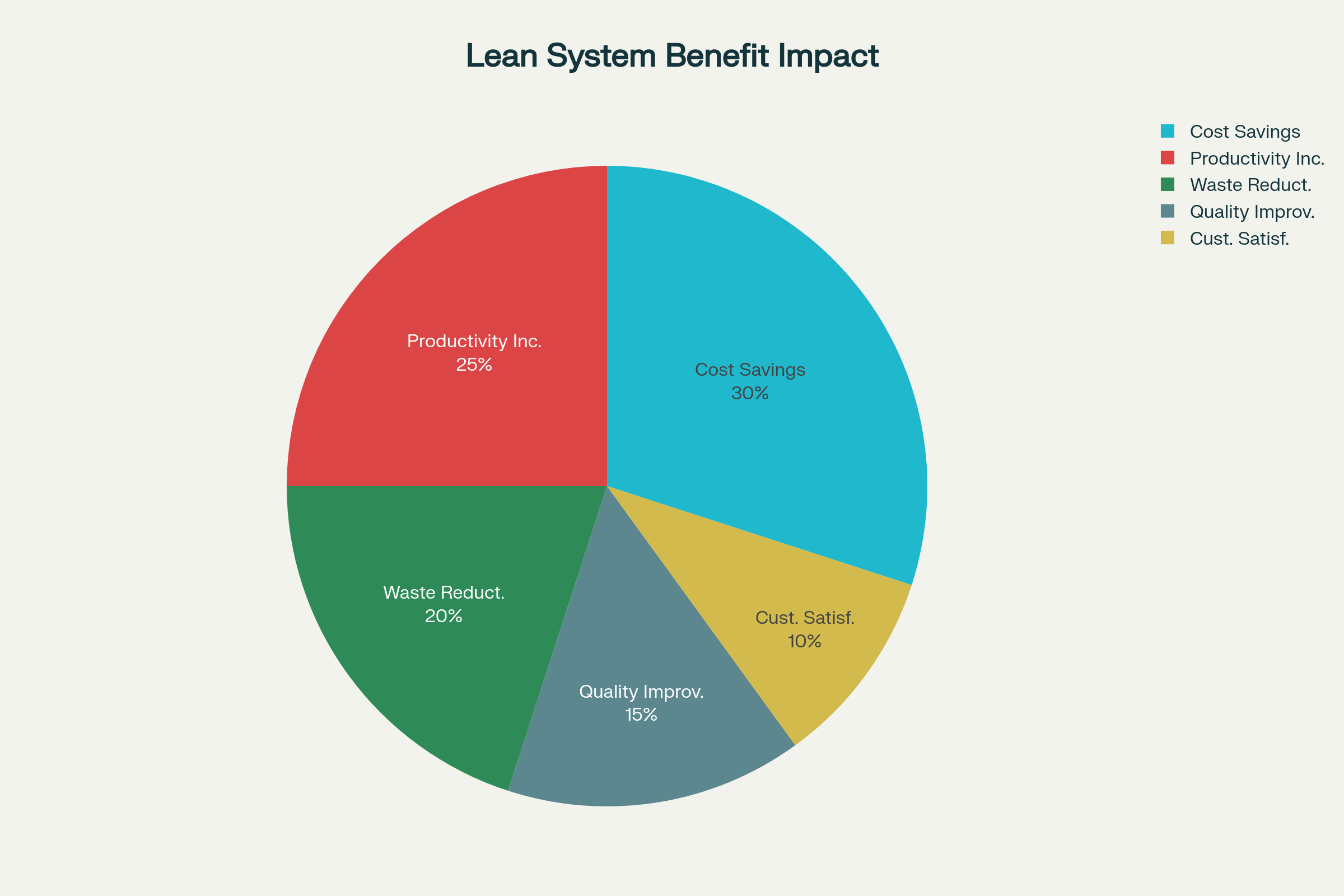

Benefits of Lean Systems

Implementing Lean doesn’t just cut costs—it transforms performance across the board58910:

- Reduction in operational costs: Less inventory, fewer errors, less rework bring major savings.

- Faster production cycle time: Shorter lead times and faster responses to customer demand.

- Improved product quality: Quality is built into each step, reducing defects.

- Higher customer satisfaction: Consistent quality and prompt delivery strengthen loyalty.

- Better team collaboration: Lean empowers employees to find and solve problems.

Impact Distribution of Key Benefits of Lean System Implementation

Problems Addressed by Lean Systems

Lean tackles many of the root causes of inefficiency and frustration in organizations today, including1112:

- Overproduction: Making more than what’s needed.

- Inventory waste: Excess material or products waiting around.

- Motion waste: Unnecessary moving of people or equipment.

- Defects/rework: Errors or mistakes that require fixing.

- Waiting time: Idle time while people or machines wait for work.

- Underutilized talent: Not making the most of employees’ skills.

Ishikawa Diagram of Wastes Tackled by Lean Systems

Infographic: Ishikawa (Fishbone) Diagram—Wastes Lean Tackles

5 Global Companies Successfully Using Lean Systems (Recent Examples)

Here’s proof that Lean makes a difference:

| Company | Year/Period | Lean System Used | Outcome/Result |

|---|---|---|---|

| Toyota | Ongoing | Kaizen, JIT | Continues to lead in quality & agility13 |

| Amazon | 2022–24 | Lean warehousing, Robotics, 5S | Faster deliveries, high warehouse efficiency |

| Nike | 2020–23 | Lean manufacturing, 5S (Asia) | Reduced waste, better worker engagement13 |

| Intel | 2021–25 | Lean Six Sigma, Kaizen | Shorter chip cycle time, defect reduction13 |

| Boeing | 2021–24 | Value Stream Mapping | Improved assembly line productivity |

Conclusion

Today’s most competitive organizations rely on Lean to reduce waste, improve quality, and delight customers. The best part? Lean principles are not just for big manufacturers—even small businesses can get started by decluttering, standardizing, and making tiny daily improvements in their workflow.

What’s slowing you down or wasting effort? Apply the Lean mindset—start small, but start now!

Sources:

- https://asq.org/quality-resources/lean

- https://www.beewatec.com/en/blog/what-is-lean-definition-lean-management-methods-and-principles

- https://theleanway.net/what-is-lean

- https://en.wikipedia.org/wiki/Lean_manufacturing

- https://www.planview.com/resources/articles/essential-principles-lean-system/

- https://www.simplilearn.com/lean-methodology-article

- https://www.manutan.com/blog/en/glossary/lean-management-definition-and-tools

- https://kaizen.com/insights/definition-advantages-lean-management/

- https://www.mingosmartfactory.com/the-top-7-benefits-of-lean-manufacturing/

- https://www.iobeya.com/blog/5-key-benefits-lean-management/

- https://geoleanusa.com/5-manufacturing-problems-that-can-be-solved-with-lean/

- https://blog.kainexus.com/improvement-disciplines/lean/7-wastes-of-lean/everyday-examples-of-the-8-wastes-of-lean

- https://shoplogix.com/nine-companies-that-use-lean-manufacturing/

- https://theleanway.net/The-Five-Principles-of-Lean

- https://www.wevalgo.com/know-how/lean-management/lean-methods-tools

- https://www.asme.org/topics-resources/content/7-examples-of-lean-manufacturing-in-action

- https://www.leanproduction.com/top-25-lean-tools/

- https://www.machinemetrics.com/blog/lean-manufacturing-problems-and-solutions

- https://www.learnleansigma.com/continuous-improvement/lean-manufacturing/

- http://www.leansystemsinc.com/lean_defined.html